Our business activities cover a wide range of production, export and import activities. We are producers of low carbon & medium carbon Ferro-alloys, aluminium powder, ingots, coarse powder (aluminium fines) as well as recycled aluminium ingots and related products. We also import scrap and Ferro-alloys. With a wide portfolio of products, we have built and defined our expertise through excellence and innovative spirit in the industry..

The Plant (Unit I)

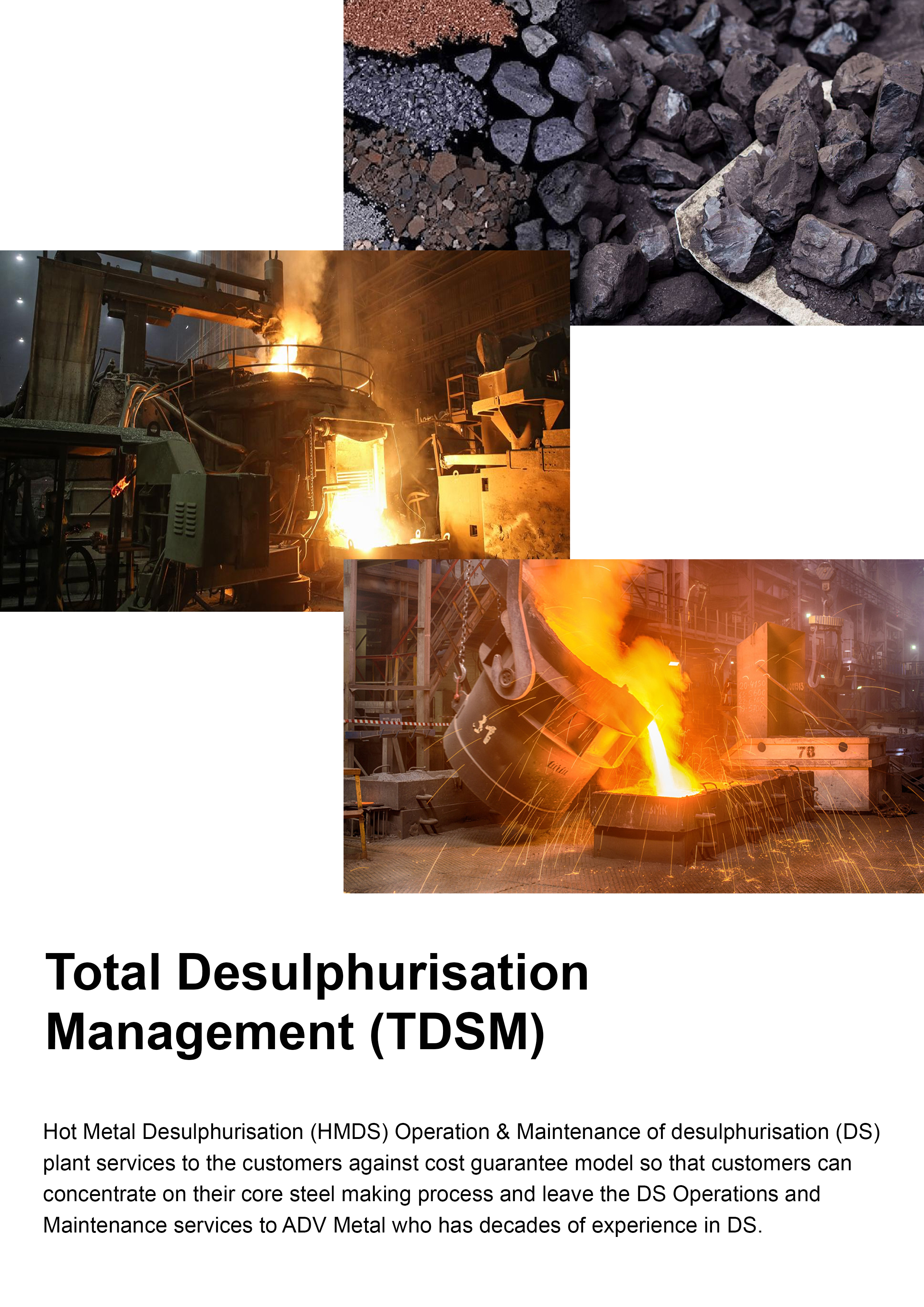

Our plant, located at Durg, has capacity to produce 10,000 tons of De-oxidation/Desulphurisation products per annum on a single shift basis. The plant capacity is proposed to be increased to over 25,000 tonnes per annum by adding certain balancing facilities to meet the potential demand in future. Our plant is capable of producing various types of Desulphurising Compounds based on calcium, aluminium and /or magnesium. Our plant is equipped with the latest controls and instrumentation system to ensure 100% safe and continuous operation and also to attain the desired product quality consistently. The construction of the plant was started in March 1999 with exclusive know-how available to a few plants around the world in the field of Desulphurising reagents in the Japanese market.

Unit II

We started our ferro alloy production through the alumino-theric process. We entered into technical collaboration with Bhabha Atomic Research Centre, Trombay in 2004 and after establishing the production process by mid-2004. Our quality is approved by many reputed alloy steel manufacturing companies in India. As per the agreement with BARC, we are not allowed to export our product.